01

Aug 22The milling machine

- August 1, 2022

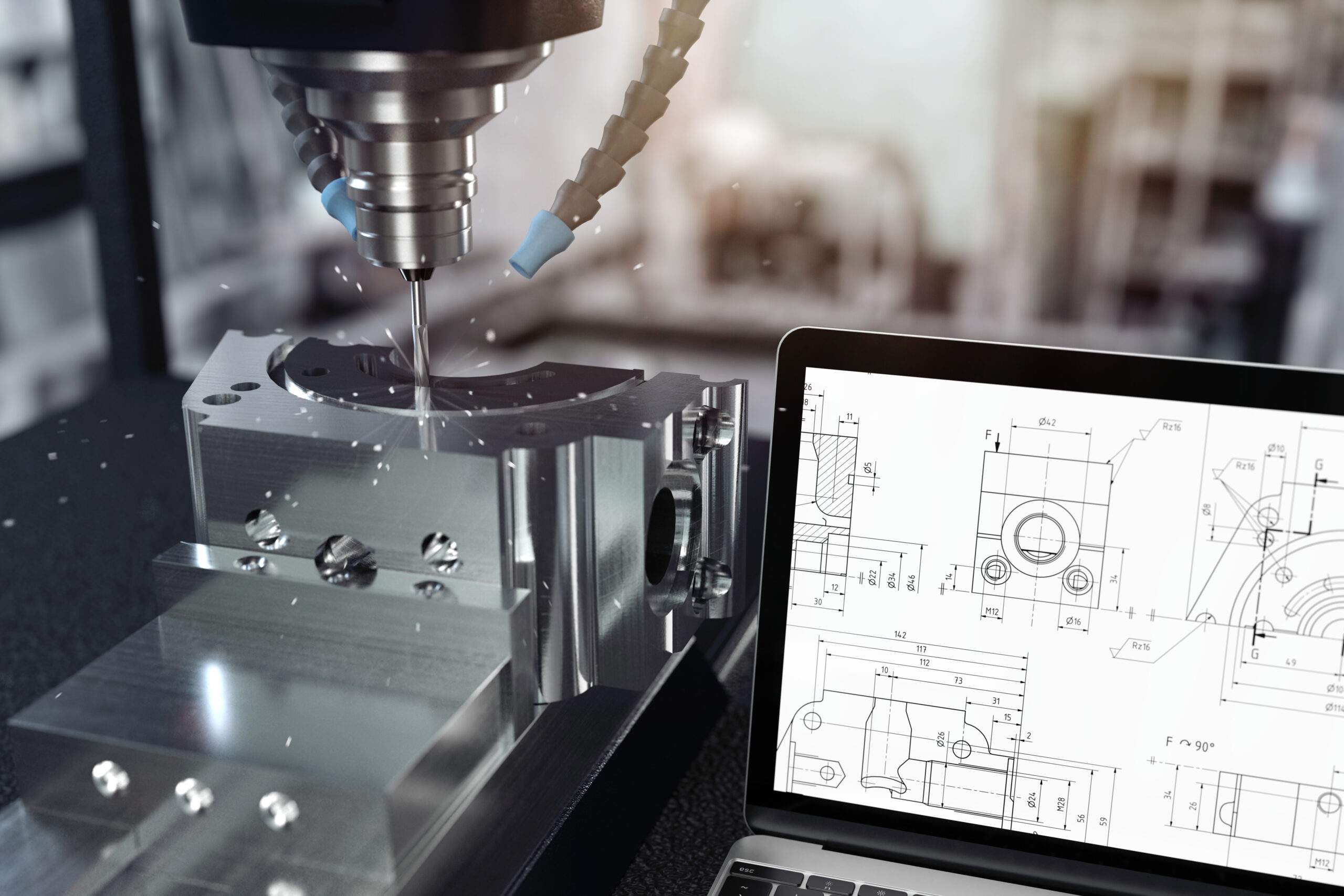

The milling machine is a machine with tools, called milling cutters. This machine roughs the piece. If you decide to buy it, you also need a locking machine,

2) a smaller machine that allows you to assemble the milling cutter composed of the body and the tip, which is the one that roughs the piece and is also the interchangeable part. It changes depending on the type of machining.

2) The milling cutter is assembled on the spindle, a mechanical arm that is part of the internal body of the machine. It moves on 3 axes, but it can even move up to 5 axes. The movement it makes is circular, in fact if you look closely at a milled mould, you can see many small circles all over the piece, obviously before finishing.

The principle is similar to that of the drill, but milling cutters are designed to perform the cutting action on the side of the tool instead of on the tip, thus by eroding the material instead of drilling it. The milling machines can be controlled manually or with CNC (computer numerical control), the most innovative ones are equipped with automatic tool change systems, which can make the production process fully computerised.

Starting from raw material, it is possible to obtain a finished part without human touch, so machining is faster and cheaper. They are big machines for two reasons: they must be stable and they must absorb a lot of vibrations. Erosion is the combination of many small vibrations. There are also nozzles that spray air or water with oils onto the piece in order to cool the machining. There are two types of milling machines: Vertical: it has a horizontal plane X-Y and a motor assembled on a vertical Z axis, the combination of the movement on the three axes produces three-dimensional paths and allows the machine, by only moving on the Z axis, to make holes. The tool works on the vertical axis.

- Vertical: it has a horizontal plane X-Y and a motor assembled on a vertical Z axis, the combination of the movement on the three axes produces three-dimensional paths and allows the machine, by only moving on the Z axis, to make holes. The tool works on the vertical axis.

- Horizontal: the horizontal milling machine has the plane X-Y, but the motor is assembled on a lateral slide. They are mainly used to level blocks of material or to create splits.

This is how a milling machine works. This tool is used for mechanical moulding. Milling machines are also ‘friendly giants’. They are big, but their machining operations are delicate and precise. When a problem occurs, the machine stops and waits for the operator’s instructions.